唯有『工業軟件』自主可控,方可解『中國智造』之憂。

Source | Lei Fengwang

Since the industrial internet was first included in the government work report last year, it has been classified as one of the key directions of "new infrastructure" since the beginning of this year, and the development of the industrial internet has been on the rise.

During the National People's Congress and the National People's Congress this year, the popularity of the "industrial internet" surged again, and the related industrial software also sparked more discussions among people.

Zhou Yunjie, a representative of the National People's Congress and President of Haier Group, brought the proposal of "Suggestions on Supporting the Development of Industrial Internet and Accelerating the Upgrading of Industrial System". For industrial software, he mentioned "concentrating advantageous resources, focusing on the research and development of industrial software and industrial apps, and establishing an open source ecosystem

At the same time, Sun Pishu, a representative of the National People's Congress and Chairman and CEO of Inspur Group, proposed suggestions to promote the in-depth development of industrial internet and promote digital transformation and development. Sun Pishu stated:

Accelerate the construction of a talent team for industrial app developers, build an innovative ecosystem for industrial internet app applications, and encourage different enterprises to cooperate in the joint development and promotion of industrial software applications

Why are these two representatives of the National People's Congress of the Chinese business community so concerned about the development of industrial software and industrial apps in China, as the 'powerful' 'Made in China' has all the industrial categories listed in the United Nations Industrial Classification? With the development of the industrial internet industry entering the fast lane, how has the industrial software that matches it developed?

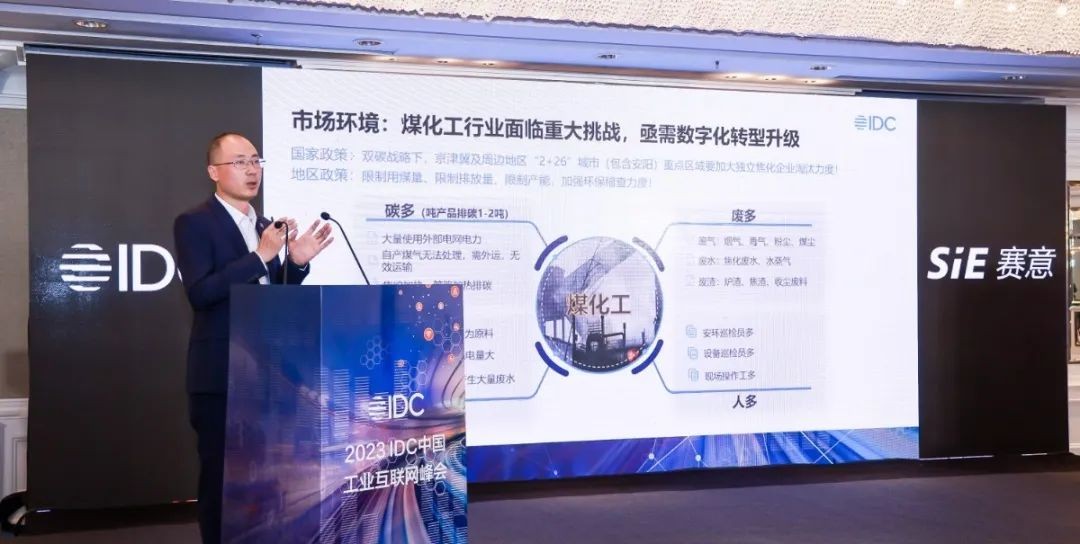

Lei Feng.com recently interviewed companies such as SiE Information, Shugen Internet, and Kunlun Data to exchange ideas on the current situation of industrial software in China, the response strategies of industrial internet platform manufacturers, the continuous iteration of industrial software, and how to better serve 'China Intelligent Manufacturing'.

It is reported that in November 2018, SiE Information and Huawei Cloud jointly released the SiE Industrial Internet Platform, in order to release their years of accumulated capabilities in the manufacturing industry and become the "third pole" force in the industrial internet field.

Speaking of the current development status of industrial software, Cai Shenglong, Vice President of SiE Information and General Manager of Industrial Internet Subsidiary, summarized his observations on this industry and stated:

The overall situation of industrial software in China is that management software is relatively strong, engineering software and R&D design software are relatively weak, and there are more low-end software and fewer high-end software. Therefore, domestic manufacturing enterprises have long relied on foreign software in many business areas

Industrial software, as an indispensable part of the digital and intelligent upgrading and transformation of industrial enterprises, is gradually receiving attention, and its own problems are constantly becoming prominent.

01 The biggest weakness of China's manufacturing industry: industrial software

Industrial software, as the crystallization of long-term industrial knowledge and experience accumulated in industrialization, is an indispensable companion in the process of industrialization. It can not only control the operation of products and equipment, but also display their running status in real-time, analyze and optimize them, and then apply them to the operation of products and equipment, even the design process, and then achieve iterative optimization.

Tracing its development, we can find that since the 1960s, foreign aerospace giants such as Boeing, Lockheed, NASA have been cultivating and developing industrial software; In the explosive period of industrial software development in the 1970s, foreign companies such as arms dealers and automobile manufacturers also decisively participated; In the early 1980s, with the emergence of IBM mainframes, VAX mini computers, and Apollo workstations in China, some CG and CAD industrial software accompanying them gradually became accepted by the Chinese people.

Subsequently, a large number of new industrial software products emerged in the industry, gradually expanding their professional scope from manufacturing to energy, raw materials, and other fields. Mergers and acquisitions occurred among enterprises, ultimately evolving into today's industrial software market pattern, giving birth to industrial software giants such as Siemens, PTC, and Schneider Electric.

Lei Fengwang learned that from 2001 to 2006, Siemens successively acquired multiple MES manufacturers and launched its own MES software Simatic IT based on this. In 2007, Siemens acquired American PLM company UGS for $3.5 billion and established the Siemens PLM Software Division. Afterwards, dozens of software acquisitions were initiated for Innotec, LMS, TESIS, Camstar, Mentor Graphics, among others. As a result, Siemens has become the second largest software company in Europe after SAP and one of the world's top ten software suppliers.

Dr. Boleren, Vice CEO of Siemens AG, stated:

Over the past two decades, Siemens has invested over $10 billion in software, putting us in a leading position in industrial software

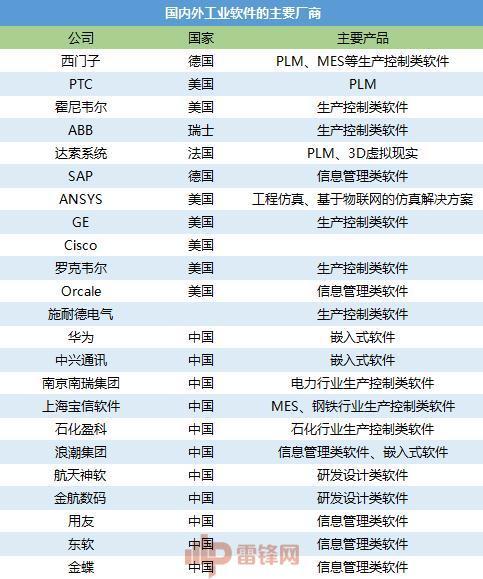

Generally, we classify industrial software into R&D and design software, information management software, production control software, and embedded industrial software.

Industrial enterprises use a lot of industrial software, including CAD and CAE for research and development design, ERP and CRM for information management, MES and PLC for production control, as well as embedded software, which is specialized software embedded in specific devices.

In order to provide a more intuitive explanation of domestic and foreign industrial software and major manufacturers, Lei Fengwang has specially summarized the enterprises, countries, and main products in this field, as shown in the following figure:

A person familiar with the matter said, "If Siemens Germany now bans NX software that integrates product design, engineering, and manufacturing in the Chinese civil nuclear industry, it will be a disaster: all models designed using NX software and the management of production and manufacturing processes will be interrupted, and the entire industry will be greatly affected, even unable to operate normally

In addition, during the ZTE incident, Cadence, an American electronic design automation (EDA) company, responded to the call of the US Department of Commerce in April 2018 to ban the sale of electronic design software, giving ZTE a heavy blow: "The discontinuation of electronic design software priced at less than millions on the procurement list will turn billions of chips into silicon earth

It is understood that the problem with private software is that users purchase a license but do not have ownership or control of the software, and the license can be revoked at any time.

Therefore, there is a viewpoint that "industrial software is the biggest weakness of China's manufacturing industry." So, what is the current situation of China's industrial software development?

In terms of the overall situation, SiE Information has summarized it as "strong management software, weak engineering software, more low-end software, and less high-end software." In addition, Cai Shenglong stated:

The standards for domestic industrial software are actually not clear, and some system architectures are relatively backward, and the integration ability to provide standards externally is not very strong. In the implementation process, it will actually affect some of our information and business systems, including the integration of this automation system. Of course, domestic embedded development software is relatively good, such as Huawei

In addition, there are already a certain number of industrial software companies in China, but they have achieved relatively good growth in the general software market. In areas with stronger and more core industrial attributes, such as industrial data modeling and virtual simulation, which involve some complex core technologies of mathematical operations, it is still necessary for everyone to continue to strive to break through

As an independent industrial internet platform manufacturer from the previous IoT department of Sany Heavy Industry, Shugen Internet's ROOTCLOUD platform is now an important member of the "national team". Regarding this, Tree Root Interconnection states:

Currently, the positioning of many industrial software is still a tool that requires professional personnel to maintain and use. As a universal tool, there is still a serious shortage of technical personnel in traditional industrial manufacturing enterprises, including software developers and intelligent technologies, in terms of informatization. Especially now, the consumption of the Internet has led to a large number of software informatization personnel from traditional manufacturing enterprises The industry is moving towards emerging internet companies

Kunlun Data, founded in 2014, has launched its flagship products, the industrial big data platform KMX and the industrial internet platform KSTONE, and is further exploring industrial software in proprietary fields. When it comes to the part of industrial software in external empowerment, they expressed:

There are many bottleneck issues in the development of China's manufacturing industry, among which industrial software is one. In addition, there are also issues with the inability to produce high-end manufacturing core equipment such as lithography machines and evaporation plating machines, as well as some cutting-edge product core processes. Of course, industrial software is the long-term accumulation and accumulation of industrial innovation knowledge, and is the brain of industrial product design and production. Currently, 80% of research and development design software and 60% of production control software are imported products Card occupation. Under the strategy of becoming a manufacturing powerhouse and the current complex international situation, there is a strong demand for localization and autonomy

In the critical period of accelerating from 'Made in China' to 'Made in China', industrial internet platform landing projects inevitably use these industrial software. So, how can our industrial internet platform manufacturers solve this part of the work when upgrading and transforming industrial enterprises into digitalization and intelligence?

How can 02 platform manufacturers' adapt 'to industrial software challenges?

In December 2018, the Ministry of Industry and Information Technology proposed the policy guidance of "accelerating the software transformation of industrial technology and accelerating the digital transformation of manufacturing industry".

Li Ying, from the Information Technology and Software Services Department of the Ministry of Industry and Information Technology, stated at the Industrial Technology Softening Special Forum and the "Million Industry APP Lecture Hall" that the Ministry of Industry and Information Technology is actively supporting various forces to jointly promote the implementation of industrial technology software engineering through various forms.

Li Yizhang, Chairman of Suowei System, pointed out that currently the two fields of artificial intelligence and manufacturing cannot be integrated and interconnected, and it is necessary to rely on industrial technology software to break down the barriers. The core of implementing industrial technology software is industrial apps. He stated:

When industrial software resources are integrated into industrial internet platforms, future developers and users of industrial apps will no longer need to purchase these expensive industrial software

In addition, as the scenarios that require empowerment in the industrial field become increasingly complex, the requirements for digitization and intelligence become higher, and the required industrial software becomes more diverse. For example, in 2020, Xinyi created the "X-PORT Port Safety Production Artificial Intelligence Management System", empowering multi-dimensional scenarios such as port logistics, operation and maintenance, safety production, and efficient operation. This system includes one platform (safety production management platform), three subsystems (port visitor appointment management system, container yard channel personnel safety control system, port bridge crane safety operation AI visual assistance system), and one hardware (port safety production special camera). It is an industry level intelligent control system launched for intelligent upgrading of ports.

So, how do some industrial internet platform manufacturers solve the problem of industrial software when implementing projects? How to achieve adaptability in an environment where there are more low-end software and fewer high-end software?

When Shugen Interconnect is engaged in digital and intelligent transformation and upgrading for industrial enterprises, such as in production control, data collection, equipment management, energy consumption management, and after-sales service management, they have always adopted a self-developed model with industrial partners. That is to SaaS traditional industrial applications, allowing these industrial application software to grow on their root cloud platform. The root cloud platform provides platform services, and based on this service, it is then used by traditional industrial enterprises based on tree root interconnection industrial software or industrial APP of industrial enterprise partners.

There are two sources for the application and development of its industrial software: one is Sany Heavy Industry, which has deep applications in product intelligence, research and development, manufacturing, and services. Therefore, they have summarized a set of industrial software that is not only suitable for construction machinery, but also can be used across industries and fields; Another is the experience gained from the nearly four years of independence of Tree Root Interconnect, which has served over 300 industrial enterprises. At present, the industrial software independently developed by Shugen Internet includes cloud vision applications, IFSM for intelligent on-site service process management, cloud networking, cloud control, unlocking machines, location management for engineering machinery management, as well as some industrial applications related to manufacturing in the factory, such as root cloud artisans and root cloud energy management.

Industrial software covers a wide range of fields, such as SCADA, PLM, CAD, CAE, and EDA, which is currently highly popular; In addition, there are also some management software, including advanced scheduling software, industrial software such as APS and MES for production control. For SiE Information, how did they solve it?

As an industrial internet platform manufacturer, SiE Information solves the problem of industrial software from two aspects: independent research and development and software integration.

In terms of independent research and development, we have created a SCADA system, also known as SMDC, mainly to meet the scene requirements of online device connection monitoring. "Cai Shenglong said:

It supports all standard protocols on the market, and for some non-standard protocols, it also supports conversion and adaptation. In the manufacturing industry, our company actually started investing in industrial software many years ago, including MES, APS, etc., which has already formed a complete product system and has been widely used in various industries such as home appliances, furniture, semiconductor machining, etc

In terms of software integration, Lei Fengwang learned that there are several types of industrial software that are currently relatively weak in China, such as research and development and design, including CAD and CAE simulation systems, as well as DCS systems for controlling proprietary industrial equipment. These systems have always been closely connected to hardware manufacturers and advanced manufacturing equipment from abroad. In these fields, foreign software companies such as PTC, Dassault, and Siemens have actually formed absolute advantages in the market. Many industrial enterprises are already using these software, and SiE Information mainly provides integration solutions to customers in different industrial scenarios to ensure deep integration in the industrial control process and improve their overall management efficiency.

The digitalization and intelligent upgrading of industrial enterprises is a gradual work, and we focus on the fields of digitalization and intelligence. It is a complementary and intelligent relationship with automation and information software, "Kunlun Data stated:

Most of the enterprises we serve have already achieved a relatively good degree of industrialization, and we are more often additive or peripheral rather than replacing them. Therefore, we will actively promote cooperation with various industrial software and hardware manufacturers. At present, our industrial software or industrial apps include applications such as equipment fault warning, equipment operation efficiency improvement, industrial safety, and product quality optimization

Industrial software and industrial apps not only require platform enterprises to seek solutions based on market demand, but also need to continue to exert efforts at key points to meet the needs of industrial enterprises and improve the market competitiveness of domestic industrial software and industrial apps.

03 Continuous iteration of industrial software

Due to the fact that industrial software is the technological invention and accumulated experience of countless intelligent people, it has been repeatedly verified in various industrial scenarios, and has been continuously iterated and optimized over the years. But how long is this time span? 20 years? 30 years

Lei Fengwang learned that even technology giants such as Apple and Google find it difficult to quickly make a difference in the field of industrial software, as no amount of product creativity and technological strength can cross the time threshold of mature industrial software.

In the current situation where "industrial software is the biggest weakness of China's manufacturing industry", how can players of industrial software and industrial apps in China exert their efforts? How to continuously iterate step by step?

This continuous iteration relies on multiple aspects, "said SiE Information Cai Shenglong:

The continuous deepening of the scene, such as a chip, 25 nanometers are different from 14 nanometers, 7 nanometers, and 5 nanometers. When experts study 25 nanometers, they only encounter some problems with 25 nanometers, and they are completely unable to understand the problems that may arise with 14 nanometers, nor the problems that should be encountered in the 5 nanometers process

The accumulation here is very solid, step by step forward, and only through this gradient can we gradually solve our problems in this field. This long-term data accumulation and long-term practice in application scenarios can truly solve this continuous iteration problem, and it is difficult to solve it through leapfrog development

In addition, Cai Shenglong also mentioned the talent and technology aspect, stating:

In fact, this aspect also needs to be continuously invested, because the investment cycle in the industrial software field is long and the iteration is relatively slow. For many enterprises, the return on this investment is actually difficult to achieve in the short term, so at this time, it is actually necessary for industry leaders to lead. For example, the aircraft manufacturing plant like Lockheed in the United States is essentially an industrial design company, which requires a lot of talent, software, and environmental protection The support of environment and ecology relies on the guidance of the country and the establishment of the ecology of leading enterprises to form this accumulation and gradually break through

Shugen Interconnection is a product of Sany Heavy Industry, which has strong industrial attributes and is very familiar with some of the needs of manufacturing enterprises. "When it comes to building industrial software, Shugen Interconnection stated:

When developing self-developed software, the first type is how to delve into some usage scenarios of industrial enterprises, and truly make this industrial software have this value. It is very important to delve into these scenarios. Secondly, try to meet the needs of industrial enterprises as much as possible, and achieve plug and play, so that customers can meet some of their needs without or with little development

Our self-developed series of software for full lifecycle management of OEM equipment actually summarizes more than ten years of experience in off-site equipment management from Sany Heavy Industry. Currently, it has been widely used among customers in various industries

In addition, Leifeng.com learned that Shugen Internet has also worked with industry leading customers to create industrial application software specifically for specific industries. For example, they have collaborated with Weihua Heavy Industry to create a lifting cloud, Jack to create a textile cloud, Jufa to create a boiler cloud, and Fanuc to create a CNC cloud.

In the view of Kunlun Data, in the process of integrating information technology, data technology, and industrial technology, creating industrial software or industrial apps will face difficulties in integrating software ecology and production and operation processes, significant challenges in the research and development of industrial app content, and difficulties in large-scale application and replication of industrial apps. The specific situation is as follows:

1. The integration of software ecology and production and operation processes is difficult. Integrating industrial apps into business processes to generate perceived landing value requires the integration of knowledge from multiple professional fields. This places higher demands on both industrial app providers and consumers, so industrial apps need a good definition and integration approach. Kunlun Data is a field where data-driven effects are easy to exert, such as equipment operation and maintenance, manufacturing execution, supply chain, etc;

2. The development of industrial APP content poses great challenges, especially for knowledge-based apps. On the one hand, there is uncertainty in expert knowledge, and on the other hand, industrial data is not comprehensive and accurate enough. IT technology also needs to have the ability to simplify the complexity of industrial scenarios when supporting iterative verification of expert knowledge and data. Kunlun Data has gradually evolved and internalized its methodology and tools into its core competitiveness in defining business problems that data can solve, as well as the experience behind problem-solving. They believe that to some extent, this will help their customers avoid detours and reach the fundamental value;

3. The large-scale application and replication of industrial apps are difficult. This includes challenges in data technology (data inconsistency, network and communication issues, etc.) and promotion, operation and maintenance costs. Kunlun Data solves these challenges through lightweight self maintenance end side products and flexible and highly adaptable data mapping technology.

Industrial software and industrial apps encode the laws of various industrial production processes, supporting the vast majority of production and manufacturing processes. How can China's industrial software industry better serve industrial enterprises and prevent them from being stuck in the crisis during the acceleration of 'China's intelligent system'?.

04 How to better serve 'China Intelligent Manufacturing'

At present, the industrial Internet industry is at the top of the wind. The Ministry of Industry and Information Technology's Guiding Opinions on Deepening the "Internet plus Advanced Manufacturing Industry" and Developing the Industrial Internet once proposed that 3-5 industrial Internet platforms with international competitiveness should be formed by 2025, and millions of industrial APPs should be cultivated and millions of enterprises should be put on the cloud.

However, due to the difficulty of achieving leapfrog development in industrial software and industrial apps, how can our industrial software and industrial apps keep up with the rapid progress of the industrial internet industry at this stage?

SiE Information Cai Shenglong believes that there are three main points, specifically:

1. Firstly, because the industrial scene is very complex, it is a very large ecosystem. So for all industrial software companies, I believe we need to solve problems solidly one scenario at a time;

2. Furthermore, for the formation of an ecosystem of industrial software standards, everyone should work together and develop it throughout the entire ecosystem;

3. Finally, we need to provide a better environment for industrial talents to continuously innovate. The return on long-term investment by enterprises may require guidance and promotion from certain national policies.

Kunlun Data believes that industrial software and industrial apps should quickly respond to the needs of industrial enterprises in the future, such as lightweight and independent; For value driven and cost considerations, it also needs to be able to match the current development status of industrial enterprises; In addition, it is necessary to focus on bold independent innovation and try data-driven, new technologies, and new ideas.

In addition, in order to better serve 'China Intelligent Manufacturing', it is necessary to 'create more industrial software that we can independently control.' Shugen Interconnect believes that whether it is a platform based service enterprise like Shugen Interconnect or some industry-specific software service enterprises, Shugen Interconnect will be committed to creating a very complete platform with very powerful machine data access capabilities, Including the access capability of software applications rooted in the Gen Cloud platform.

Lei Fengwang learned that for service-oriented industrial software, Shugen Internet believes that it should continue to deepen into this industry, continuously improve the attributes of some industries, and continuously upgrade and improve from segmented industries. This is not only to meet some of the needs of enterprise users, but also to guide the production and operation management of enterprises and be a teacher of enterprise production and operation management. Tree Root Interconnection can provide a foundation for platform enterprises and services for some software service enterprises in the industry. The combination of the two can provide comprehensive information services for Chinese manufacturing enterprises.

After the two sessions, where should the industrial software that restricts the development of China's manufacturing industry go? Will there be any new policies at the national level?